Smart cooking zones for East Africa

We support the prototype production for a sustainable development aid concept from SEMINA

SEMINA is Michael Keinrath and Simon Brockmeier from Graz, who have been working as engineers on development aid projects in East Africa since 2018. It struck them how much can still be done here, especially to enable the families living in great poverty to improve their everyday processes.

Produce Coal while cooking

For example when cooking: In East Africa, most cooking is done on open fires. Smoke collects in the room under the canopies of the cooking areas, making it hard to breathe. According to the WHO, 3 billion people worldwide are affected by such domestic air pollution caused by cooking over open fires, and 3.8 million people die from the health consequences of the pollution. At the same time, households must spend 30 % of their income on cooking fuel alone. There are solutions for clean cooking stoves, but the people who need these technologies most do not have access or simply cannot afford them.

This is where the SEMINA concept comes in: Keinrath and Brockmeier have developed a cooking stove that not only produces less smoke, but also provides users with an income: Their stove is heated with agricultural waste and dried biomass, thus not only generating heat for cooking, but also simultaneously converting the waste into charcoal through pyrolysis in the combustion chamber. 3 kilograms of biomass thus becomes 1 kilogram of bio-coal.

With prototypes from Müllheim

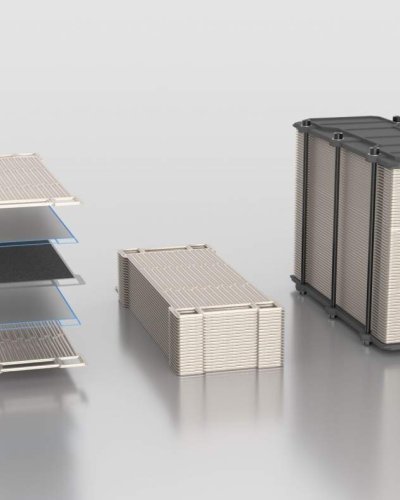

The TechCenter at Weil Technology was called in to manufacture the first prototypes of the combustion cell for the SEMINA furnaces. The first 100 combustion chambers are now being manufactured here. Weil Technology has the necessary expertise in tube production. Here, exactly the desired prototypes can be manufactured in the required quantities.

The TechCenter houses the necessary machines. Andreas Graf and Wilfried Hörsch are responsible for sample production: First, the sheets are laser cut and partially perforated in the FLC, as are the bottom rings. Then the sheets go to the RMA for round bending and to the Flexmaster for longitudinal seam welding. Then comes the challenging part: the base plates have to be inserted and welded exactly into the outer tube, before the inner tube is also inserted and welded exactly. Wilfried Hörsch achieves this challenging precision thanks to the patented clamping technology in the Flexmaster. But Michael Keinrath and Simon Brockmeier are also impressed by the clean laser-cut edges. These are exactly the parts they want.

The combustion chambers will now be assembled in the next step with the electronic components for the monitoring and mobile pay reward system in the development phase in Austria.

The first 20 finished prototypes will be launched in Uganda in September.

For a good climate on site and for all of us

In the long term, the stoves are to be produced in mobile workshops in Africa. For this purpose, SEMINA is currently building a network together with local project partners to create fairly paid jobs and support local workers with applied metal construction training.

The same applies to the financing of the furnaces: A stove costs 170 euros to purchase - a sum that a household in East Africa usually cannot afford. Therefore, the stoves are provided to the users free of charge. By selling the coal produced during cooking, they pay off the stove in the first year. For the coal produced afterwards, SEMINA remunerates 2 euros per kilo.

The coal is collected from households and picked up at regular intervals by SEMINA network partners, who process it into bio-coal briquettes that are resold in local coal markets. These briquettes, made from agricultural waste, replace coal for which entire swaths of land are otherwise cleared within days. The producer households are paid via the SEMINA app and Mobile Money - the payment system commonly used in Africa.

To further fund the project, SEMINA will also offer CO2 offset certificates for sale, as the stoves significantly reduce CO2 emissions compared to conventional burners: The smart control unit on the stoves monitors CO2 emissions and sends the collected information via Bluetooth to smartphones, which collect the data on SEMINA servers to generate 100% transparent CO2 certificates.

More about the project: Semina-Energy - We revolutionize the access to clean energy.